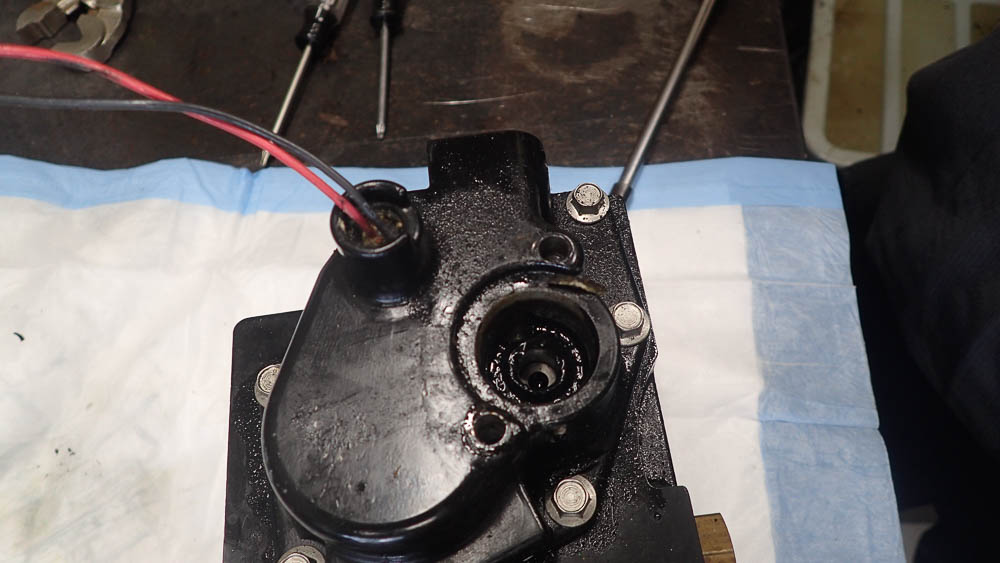

So Star Keeper has started developing an embolism. The symptoms started out as some stumbling and significantly mismatched wide open throttle RPMs. After doing some research and checking plugs, we found some articles on clubsearay.com outlining an issue with the Cool Fuel modules that were on our 8.1 Engines. It appears that the paint they use on the underside of the pump lid did not adhere properly and had a reaction with ethanol. The paint flakes off and enters the fuel path AFTER the filters. So the pump is safe but the primary pressure regulator and the injectors are subjected to the particles.

A quick check involves pulling the pressure regulator off the top of the Cool Fuel module. Its going to be pretty obvious. So I had my technician Chip take a look and he confirmed it. He reached out to Mercruiser/Sea Ray and they stated they would cover parts. Thankfully I also had an extended warranty so they covered the labor. Parts includes a new pressure regulator, new pump housing lid, and all new injectors for each engine. Parts cost was $1,200/engine though I think if you had to come out of pocket you could find some better pricing. Especially for the injectors. Since I wasn’t paying for it here it wasn’t an issue. Labor on this for a tech who has done several and fits well in the bilge runs about 9 hours for the two though me asking questions and taking pictures may have slowed him down a little bit.

A quick check involves pulling the pressure regulator off the top of the Cool Fuel module. Its going to be pretty obvious. So I had my technician Chip take a look and he confirmed it. He reached out to Mercruiser/Sea Ray and they stated they would cover parts. Thankfully I also had an extended warranty so they covered the labor. Parts includes a new pressure regulator, new pump housing lid, and all new injectors for each engine. Parts cost was $1,200/engine though I think if you had to come out of pocket you could find some better pricing. Especially for the injectors. Since I wasn’t paying for it here it wasn’t an issue. Labor on this for a tech who has done several and fits well in the bilge runs about 9 hours for the two though me asking questions and taking pictures may have slowed him down a little bit.

The gallery below gives you an idea on how to tackle this project. Since I didn’t do it myself I can’t really outline it  step by step. There are a couple of things to note. The starboard engine is much easier than the port. Pulling the port muffler gives you more room to work. MAKE SURE YOU LEAVE THE STACK ON THE UNDERWATER EXHAUST. You might be able to change the components without removing the entire unit but it was a lot easier to pull the whole thing as a unit. You will need the proper fuel line disconnect tool. We ended up hauling them to the work bench as you have to change out the cover which means pulling the connector off the pump wiring. Chip also pulled the entire fuel rail for each engine. Injectors were swapped on the bench and they are an absolute pain to get out of the fuel rail so be careful with that. Assembly was simply the reverse. There are several connections in the wiring harness that don’t connect to anything such as diagnostic ports, connections for sensors that aren’t used on this engine, etc. I was amazed as how smooth the engine was after this repair. Since we have only owned the boat since October of 2015 we didn’t have anything else to compare it to. Check out the gallery below for more pictures. Also check out our Photo Galleries.

step by step. There are a couple of things to note. The starboard engine is much easier than the port. Pulling the port muffler gives you more room to work. MAKE SURE YOU LEAVE THE STACK ON THE UNDERWATER EXHAUST. You might be able to change the components without removing the entire unit but it was a lot easier to pull the whole thing as a unit. You will need the proper fuel line disconnect tool. We ended up hauling them to the work bench as you have to change out the cover which means pulling the connector off the pump wiring. Chip also pulled the entire fuel rail for each engine. Injectors were swapped on the bench and they are an absolute pain to get out of the fuel rail so be careful with that. Assembly was simply the reverse. There are several connections in the wiring harness that don’t connect to anything such as diagnostic ports, connections for sensors that aren’t used on this engine, etc. I was amazed as how smooth the engine was after this repair. Since we have only owned the boat since October of 2015 we didn’t have anything else to compare it to. Check out the gallery below for more pictures. Also check out our Photo Galleries.

[ngg_images source=”galleries” container_ids=”16″ display_type=”photocrati-nextgen_basic_thumbnails” override_thumbnail_settings=”0″ thumbnail_width=”240″ thumbnail_height=”160″ thumbnail_crop=”1″ images_per_page=”20″ number_of_columns=”0″ ajax_pagination=”1″ show_all_in_lightbox=”0″ use_imagebrowser_effect=”0″ show_slideshow_link=”0″ slideshow_link_text=”[Show slideshow]” slug=”cool-fuel” order_by=”sortorder” order_direction=”ASC” returns=”included” maximum_entity_count=”500″]